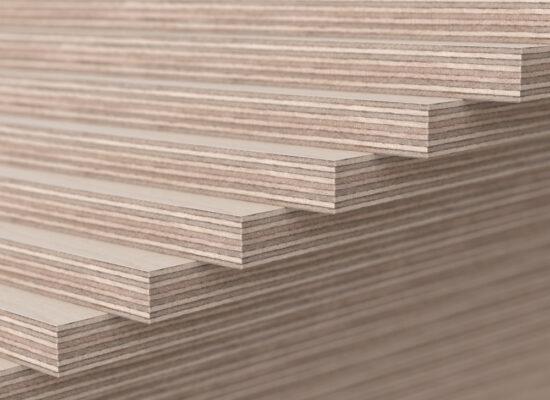

Plywood

Plywood is an engineered sheet timber product that is frequently used in building and is sometimes just referred to as “ply.” It is made from three or more thin wood veneer layers, sometimes known as “plies,” that are adhered together to create a thicker, flat sheet. It is reasonably resistant to warping and breaking, can be made to exact proportions, and is affordable.

Plywood is frequently used to build external walls or light partitions.

– Formwork.

– Furniture.

– Flooring.

– Structures systems.

– Lighting up the doors and shutters.

There are several different kinds of plywood, including:

Structural plywood, which is used for beams, formwork, and bracing panels in permanent constructions where high strength is required.

External plywood is used on surfaces outside where a decorative or attractive finish is crucial.

Internal plywood: Used to add a decorative finish to non-structural applications like ceilings and wall panels.

Marine plywood: This type of plywood is used in the construction of ships as well as in areas of buildings where there may be a lot of moisture present, such the roof or bathrooms.

Production Procedure

Softwoods (like Douglas fir, pine, and redwood) and hardwoods (like ash, maple, and mahogany) are both used to make plywood, as well as a combination of both.

Steaming or immersing the wood used to create plywood in hot water will prepare the material. Then a lathe machine peels it into thin plies that range in thickness from 1-4 mm. Then it is shaped into substantial sheets.

The face of plywood is the surface that is visible after installation, along with the back and core (which lies between the face and the back). A strong adhesive, commonly phenol or urea formaldehyde resin, is used to bond the plies together.

Each ply layer is rotated up to 90 degrees in relation to the one before it, with the wood grain running perpendicular to the adjacent layer. Cross-graining, which separates plywood from laminated veneer lumber, is what gives plywood its distinctive appearance (LVL). In plywood, the direction of the plies alternates, in contrast to the constant orientation of the plies in LVL. In order to balance the sheet and lessen warping, it is customary to have an odd number of plies.

Cross-graining lessens the plywood’s propensity to split when fastened at the edges. It also increases the dimensional stability of the material by reducing expansion and shrinkage, and it gives the panels constant strength in all directions.

When thick sheets are needed, composite plywood can be engineered. In this instance, the face and back are covered with a wood veneer over a core made of real wood or particleboard.

The addition of a thin outer coating that resists moisture, abrasion, and corrosion, as well as making it simpler to apply paint and dye, can increase the durability of the face and back veneers. Plastic, cloth, Formica, and resin-impregnated paper are a few of the materials that can be employed.

Properties

Plywood is a handy and well-liked building material due to a number of its characteristics.

High strength

Plywood combines the qualities acquired from its laminated design with the structural strength of the timber from which it is made. Cross-graining gives the sheet uniform strength for greater stability and the capacity to withstand splitting.

High panel shear

The plywood’s resistance to bending is due to the odd number of veneer layers that make up the material. Plywood can be used to brace panels and manufactured beams by increasing the panel shear.

Flexibility

Compared to cut timber, plywood can be produced to meet a larger range of requirements. The number of veneers used can be increased depending on the amount of strength needed. Veneer thicknesses can range from a few millimeters to several inches.

Moisture resistance

Due to the type of adhesive that is utilized during the binding process, plywood has a pretty high resistance to moisture and humidity. As a result, it may be useful for outside applications such cladding, shelters, concrete formwork, and marine building. The cross lamination protects the veneers against warping, shrinking, or expanding when exposed to water and temperature.

Chemical and fire resistance

Preservatives can be applied to plywood to make it resistant to corrosion when exposed to chemicals. Additionally, chemical treatments can improve the fire resistance of plywood.

Impact resistance

Plywood’s strong tensile strength from cross lamination enables it to endure overloading by up to double the intended load. It can therefore be used in formwork and flooring systems.

Insulation

Due to its excellent thermal and acoustic insulation properties, plywood can be used for wall cladding, roofing, and flooring.

© Arbemu. All rights reserved